|

Rover V8 TR4A

Okay, so I don't know when to quit.

After the less than successful Judson Supercharger installation,

I knew that I really wanted more power, but it had to be

reliable. The other rule was that it had to be true to the

character of what was done back in the 60's, so this ruled out a

modern engine swap. Finally, it could not involve cutting up the

TR4A sheet metal, I did not want to touch that lovely body

shape. The ideal engine would allow me to double my power,

retain the same weight, allow the installation of a 5 speed

transmission, and fit the available space. While at the shows

over the years, I have seen all manner of engine swaps (RX7

Rotary, Various V8's, V6's and hot 4 cylinders) but none of

these really look correct. I wanted to have a period swap, so no

fuel injection or other modern systems. So the obvious choice

was an old Rover V8. I researched the dimensions and determined

that it would roughly fit in the space available. I then

started the usual Ebay searches and research on the engine in

it's various versions (Buick/Pontiac/Olds, Rover cars, Rover

trucks, MGB/TR8, etc...). This engine has really been around.

While I found a lot of options on Ebay, ultimately I ended up

talking to a guy online that had an old Rover PB 3500 engine, a

Camaro T5 and a bell housing for sale. Figuring that this was a

fast way to get started, I drove to New Jersey and bought it on

the spot. While the engine was as described (very low mileage

and a high compression (10.5-1), it needed a full rebuild. I was

very surprised at how clean it was on the inside, having none of the usual oil buildup on the pushrod galleries. I also bought

the book "Tuning Rover V8 Engines, David Hardcastle.

the usual oil buildup on the pushrod galleries. I also bought

the book "Tuning Rover V8 Engines, David Hardcastle.

This

book was very valuable in that it went over all the various

pieces that can be swapped (or not) between the various years of

the Rover and GM versions of this engine. Because of this book,

I ended up spending many hours on Ebay, hunting down various

components that were better than what came with my engine. This

and advice from vendors like Ted Schumacher at TSImported

Automotive and Dan LaGrou at D&D really helped me get this

project together. The final specs of the engine are as follows: This

book was very valuable in that it went over all the various

pieces that can be swapped (or not) between the various years of

the Rover and GM versions of this engine. Because of this book,

I ended up spending many hours on Ebay, hunting down various

components that were better than what came with my engine. This

and advice from vendors like Ted Schumacher at TSImported

Automotive and Dan LaGrou at D&D really helped me get this

project together. The final specs of the engine are as follows:

Rover PB 3500 Block, crank and pistons

(10.5 - 1), Crower 276 degree - 488 lift Cam, Heavy

duty double roller chain and gears, Heavy duty lifters, ARP main

bearing studs and ARP rod bearing bolts. Rover SD1 Heads

with three angle valve job and new valves (bigger ports then the

stock heads), MGB block hugger headers, Offenhause 4 barrel

manifold and Edelbrock 500 CFM carb. Mallory magnetic

distributor, Mallory 8 mm wires, Bosch Platinum plugs, TS

Automotive custom flywheel, Weber clutch, hydraulic throw out

bearing, D&D GM bell housing, Camaro T5 5-speed, Hurst

Shifter, D&D custom driveshaft,

Rover SD1 valve covers, Buick 215 water pump, GM alternator,

custom motor mounts. I am estimating output at 215-225 based on

what I have researched on this engine. Heavy

duty double roller chain and gears, Heavy duty lifters, ARP main

bearing studs and ARP rod bearing bolts. Rover SD1 Heads

with three angle valve job and new valves (bigger ports then the

stock heads), MGB block hugger headers, Offenhause 4 barrel

manifold and Edelbrock 500 CFM carb. Mallory magnetic

distributor, Mallory 8 mm wires, Bosch Platinum plugs, TS

Automotive custom flywheel, Weber clutch, hydraulic throw out

bearing, D&D GM bell housing, Camaro T5 5-speed, Hurst

Shifter, D&D custom driveshaft,

Rover SD1 valve covers, Buick 215 water pump, GM alternator,

custom motor mounts. I am estimating output at 215-225 based on

what I have researched on this engine.

Okay, so now I had an engine for the car. Now I have make it fit

in the available space! I first pulled the old engine and

transmission (not that old, they have less than 10,000 miles on

them) and cleaned up the engine bay. These old engines do throw

a lot of oil even in just 10k miles. With the engine bay cleaned

up, first order was to lower the engine in the bay and see what

needed to be done. I did this exercise probably 20 times as I

checked, and rechecked possible engine/transmission locations.

Front, back, height, all had to be checked and rechecked to

ensure the engine would clear the hood and that I could route

the steering around engine.

The

final result was based on using motor mounts bolted to the stock

cross member on the frame and rising up to the stock Rover

rubber mounts. Based on this position, the headers could be fit

around the A-arm mounts on the frame (barely) and the only sheet

metal to be The

final result was based on using motor mounts bolted to the stock

cross member on the frame and rising up to the stock Rover

rubber mounts. Based on this position, the headers could be fit

around the A-arm mounts on the frame (barely) and the only sheet

metal to be trimmed was the small "points" on the upper wheel well around

the front A-arm and spring tower. This could be done and since

this is missing on both older TR4's and the 250's, probably no

one would notice unless it is pointed out. So out came the

sawsall and this was quickly trimmed. With the "points" out of

the way, the engine could be brought forward a few inches and

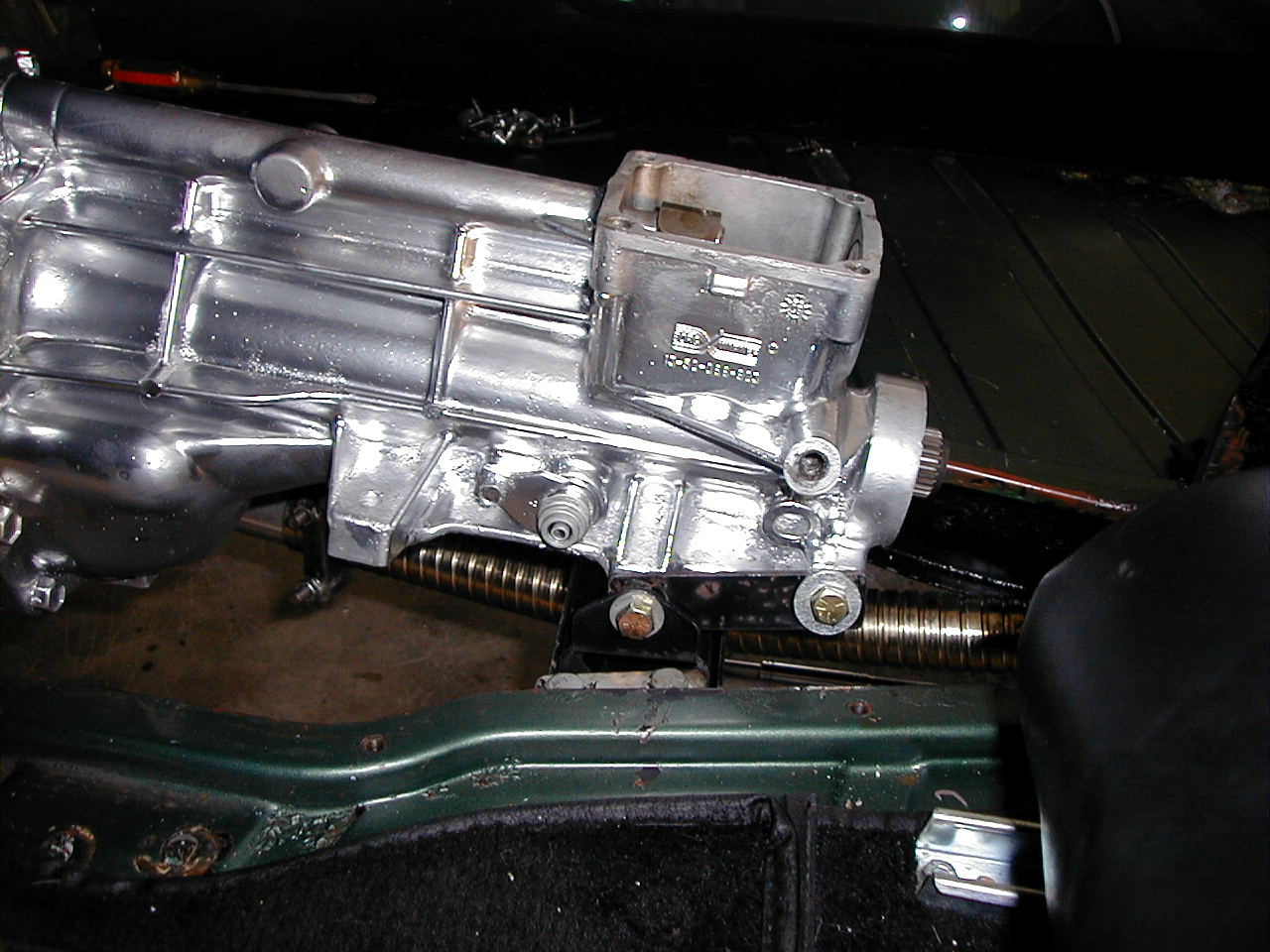

the transmission shifter was roughly in the stock position. Next

step was to weld up some motor mounts and bolt it together. The

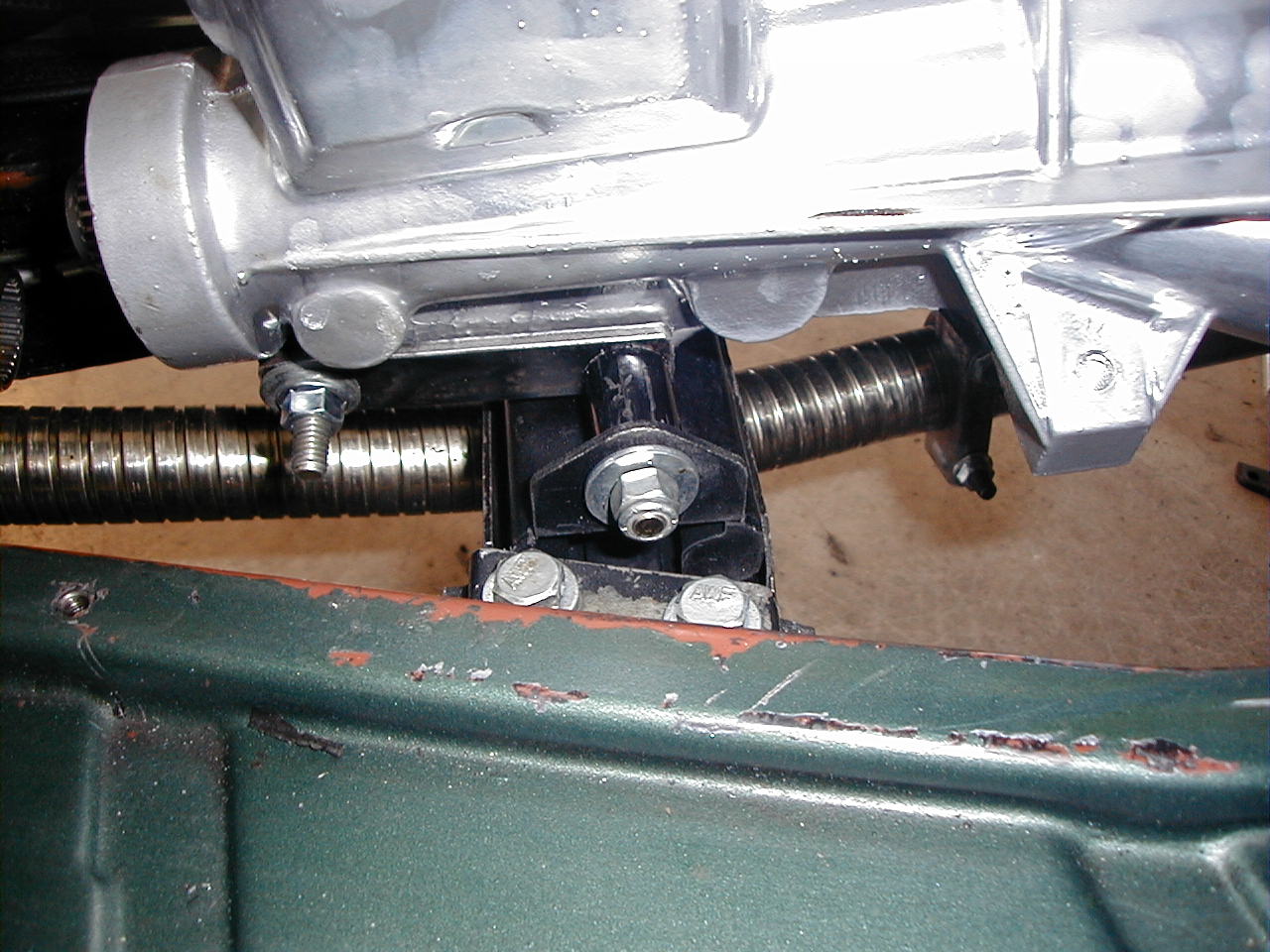

transmission mount is a combination of the stock TR4A rear mount

and the Camaro brackets on the tail of the transmission. D&D

built me a custom drive shaft to my specifications and all

bolted together as it should. The exhaust is made up of down

pipes that mate to the stock TR4A rear dual mufflers for a true

dual exhaust. Result is quieter than expected, but nothing can

hide that V8 rumble!

trimmed was the small "points" on the upper wheel well around

the front A-arm and spring tower. This could be done and since

this is missing on both older TR4's and the 250's, probably no

one would notice unless it is pointed out. So out came the

sawsall and this was quickly trimmed. With the "points" out of

the way, the engine could be brought forward a few inches and

the transmission shifter was roughly in the stock position. Next

step was to weld up some motor mounts and bolt it together. The

transmission mount is a combination of the stock TR4A rear mount

and the Camaro brackets on the tail of the transmission. D&D

built me a custom drive shaft to my specifications and all

bolted together as it should. The exhaust is made up of down

pipes that mate to the stock TR4A rear dual mufflers for a true

dual exhaust. Result is quieter than expected, but nothing can

hide that V8 rumble!

Next

step is to pull the engine back out and build the new steering

system. The only safe way to do this is use Borgeson steering

components. This company specializes in the parts to build a

heavy duty steering system that allows you to take the Triumph

splined rack fitting and adapt it to a 3/4 D shaft, using a

combination of flex joints, vibration dampeners and mountings, a

steering system can be routed around the V8 block and headers.

The result is a stronger solution with more feel than the stock

rubber donut system. Here is the routing for the steering. With

final engine placement, there were a few adjustments that were

necessary to clear everything, but this is the basic layout of

the steering system. Next

step is to pull the engine back out and build the new steering

system. The only safe way to do this is use Borgeson steering

components. This company specializes in the parts to build a

heavy duty steering system that allows you to take the Triumph

splined rack fitting and adapt it to a 3/4 D shaft, using a

combination of flex joints, vibration dampeners and mountings, a

steering system can be routed around the V8 block and headers.

The result is a stronger solution with more feel than the stock

rubber donut system. Here is the routing for the steering. With

final engine placement, there were a few adjustments that were

necessary to clear everything, but this is the basic layout of

the steering system.

With the steering settled, it was now time

to get everything back in the car. The engine and transmission

installed back with little hassle. All the components had been installed and removed

enough time so I could do it in record time (and with the clutch

problems I had, I would get more practice). With everything

bolted up, it was time to route the fuel lines, exhaust, wiring

and cooling system. I bought an aluminum "generic" radiator and

had to make my own mounts to hold this in place. Since this is

for a GM 350, I should have plenty of cooling, with the electric

radiator fan and a

little hassle. All the components had been installed and removed

enough time so I could do it in record time (and with the clutch

problems I had, I would get more practice). With everything

bolted up, it was time to route the fuel lines, exhaust, wiring

and cooling system. I bought an aluminum "generic" radiator and

had to make my own mounts to hold this in place. Since this is

for a GM 350, I should have plenty of cooling, with the electric

radiator fan and a

thermostat.

I'll build a radiator shroud when this is completed. I hooked up

the radiator and then mounted the GM alternator. The

instructions on the VTR site for installing a alternator in a

Triumph were very helpful and I modified my voltage regulator

box to hide the conversion. The difference in the headlights and

interior lights is amazing. The TR generator is such a bad joke!

I used to have to rev the engine at a stop light to be able to

see. Once everything was back together, I topped up all the

fluids and hooked up the battery. With some fear and excitement,

I cranked it over. Nothing! After several days of trying

everything (fuel, spark, etc...) I decided that I must have the

cam in backwards (180 degrees out of phase), sure enough upon a

front engine tear down, it was backwards. This is the second

time I built an engine and thought that TDC was correct only to

find it was the compression stroke. In a few hours, I had the

engine running on the jack stands. Okay, so after shifting the

car on the stands a few times and running the engine for 1/2

hour at various speeds to check for leaks, etc... I was ready to

go around the block. I lowered the car to the ground, backed it

out of the garage and started it up. When I tried to put it in

gear, it ground like the clutch was not working. Okay, so back

in the garage to check the clutch. Everything appeared in order,

but what works (at no load) on the stands does not work on the

ground. So I ended up pulling the transmission. Double checked

and triple checked the hydraulic throw out bearing clearance,

replaced the clutch master cylinder with a Wildwood unit, bleed

the system multiple times, but still no clutch. At TRF in

August, I bought a special flywheel from Ted that will allow me

to switch to a different clutch to see what the problem is. It

appears that the pressure plate may not be releasing correctly

with the Buick flywheel. The new flywheel lets me try a GM, Ford

or Rover clutch so I'll get this resolved this winter so we have

the car on the road this spring. Watch this space for an update

of how it drives! Based on how it sounds, I think a brake

upgrade will be the next step. thermostat.

I'll build a radiator shroud when this is completed. I hooked up

the radiator and then mounted the GM alternator. The

instructions on the VTR site for installing a alternator in a

Triumph were very helpful and I modified my voltage regulator

box to hide the conversion. The difference in the headlights and

interior lights is amazing. The TR generator is such a bad joke!

I used to have to rev the engine at a stop light to be able to

see. Once everything was back together, I topped up all the

fluids and hooked up the battery. With some fear and excitement,

I cranked it over. Nothing! After several days of trying

everything (fuel, spark, etc...) I decided that I must have the

cam in backwards (180 degrees out of phase), sure enough upon a

front engine tear down, it was backwards. This is the second

time I built an engine and thought that TDC was correct only to

find it was the compression stroke. In a few hours, I had the

engine running on the jack stands. Okay, so after shifting the

car on the stands a few times and running the engine for 1/2

hour at various speeds to check for leaks, etc... I was ready to

go around the block. I lowered the car to the ground, backed it

out of the garage and started it up. When I tried to put it in

gear, it ground like the clutch was not working. Okay, so back

in the garage to check the clutch. Everything appeared in order,

but what works (at no load) on the stands does not work on the

ground. So I ended up pulling the transmission. Double checked

and triple checked the hydraulic throw out bearing clearance,

replaced the clutch master cylinder with a Wildwood unit, bleed

the system multiple times, but still no clutch. At TRF in

August, I bought a special flywheel from Ted that will allow me

to switch to a different clutch to see what the problem is. It

appears that the pressure plate may not be releasing correctly

with the Buick flywheel. The new flywheel lets me try a GM, Ford

or Rover clutch so I'll get this resolved this winter so we have

the car on the road this spring. Watch this space for an update

of how it drives! Based on how it sounds, I think a brake

upgrade will be the next step.

Spring 2004 - Okay so it was time

to get this project moving again. Armed with the new flywheel, I

started attacking the clutch problem. I decided that I would

replace the clutch, disk, use the new flywheel and also rebuild

the T5 to make sure that everything was correct. I bought most

of the parts on Ebay and/or Napa/AutoZone. The T5 was stripped

down and found to be in good condition. I replaced some of the

synchronizers and adjusted the shims for the input shaft bearing

but other than that, it was basically a strip and re-assemble.

This also allowed me to seal the case with permatex which

stopped the leak it had since it was first installed (must be

because it was installed in a Triumph). Before I finished with

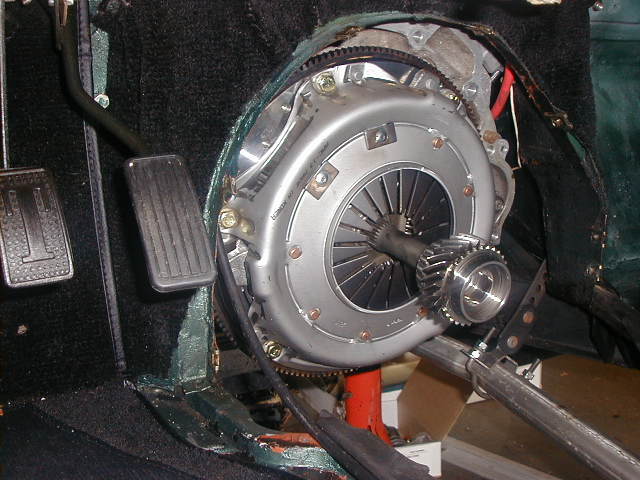

the transmission, I took the opportunity to center the clutch

with the input shaft to make sure it was perfectly centered as

below. Now that the clutch was done, I finished

the transmission and reassembled everything. Much to my dismay

after spending 5 hours on a Saturday (after many weekends of

preparation), the clutch still did not work. I pumped the clutch

pedal several times and it ended up leaking brake fluid out a

fitting on the Mcleod unit. After this, I had enough with the

Mcleod hydraulic throw out bearing. I know that people say that

these units are fine and work great, but I have had to pull the

transmission on this car so many times, that it is not funny

anymore. So my next plan was to switch to a conventional clutch

fork and external slave.

Now that the clutch was done, I finished

the transmission and reassembled everything. Much to my dismay

after spending 5 hours on a Saturday (after many weekends of

preparation), the clutch still did not work. I pumped the clutch

pedal several times and it ended up leaking brake fluid out a

fitting on the Mcleod unit. After this, I had enough with the

Mcleod hydraulic throw out bearing. I know that people say that

these units are fine and work great, but I have had to pull the

transmission on this car so many times, that it is not funny

anymore. So my next plan was to switch to a conventional clutch

fork and external slave.

After a trip to the junk

yard to look at the possibilities, I decided that a GM/Camaro

clutch fork should work together with the matching throw out

bearing and pivot bolt. After consulting with D&D, I discovered

that my aftermarket bell housing would not work as it did not

have enough clearance for the fork to exit the bell housing. So

I had them send me everything I needed. I listed the hydraulic

bell housing on Ebay as well as the Mcleod and had both reach the

asking price in a few hours! Okay, so now I have a conventional

clutch mechanism, but what to use for a slave cylinder? At first

I considered using the stock TR4 unit, but after looking at how

it would mount, decided to look for an alternative. I looked at

the Napa store at various Toyota, Nissan and GM slaves, but none

seem to suit. Finally, I found the Wilwood pull slave on the

internet. Now here was a slave that would mount under the engine

(and clear the transmission tunnel). It also mounts in a unusual

way being that it is a pulling unit, it mounts using a threaded

rod. This allows me to connect it the engine mount and it

pulls the clutch fork perfectly. It also allows me to use the

current clutch hydraulic pipes. So all this was done the

following Saturday and I started the car and gave it a test.

Guess what, I now have a working clutch. It will need some

adjustments and I have to fix a leaking fuel pump before I go on

any major rides, but the TR4A- V8 was able to travel up and down

my road under it's own power!.

Below are a few more pictures of the

clutch fork. I'll do some other pictures from underneath so you

can see the mounting for the slave cylinder soon. I have also

included the rear mount as I strengthened it with some steel

braces.

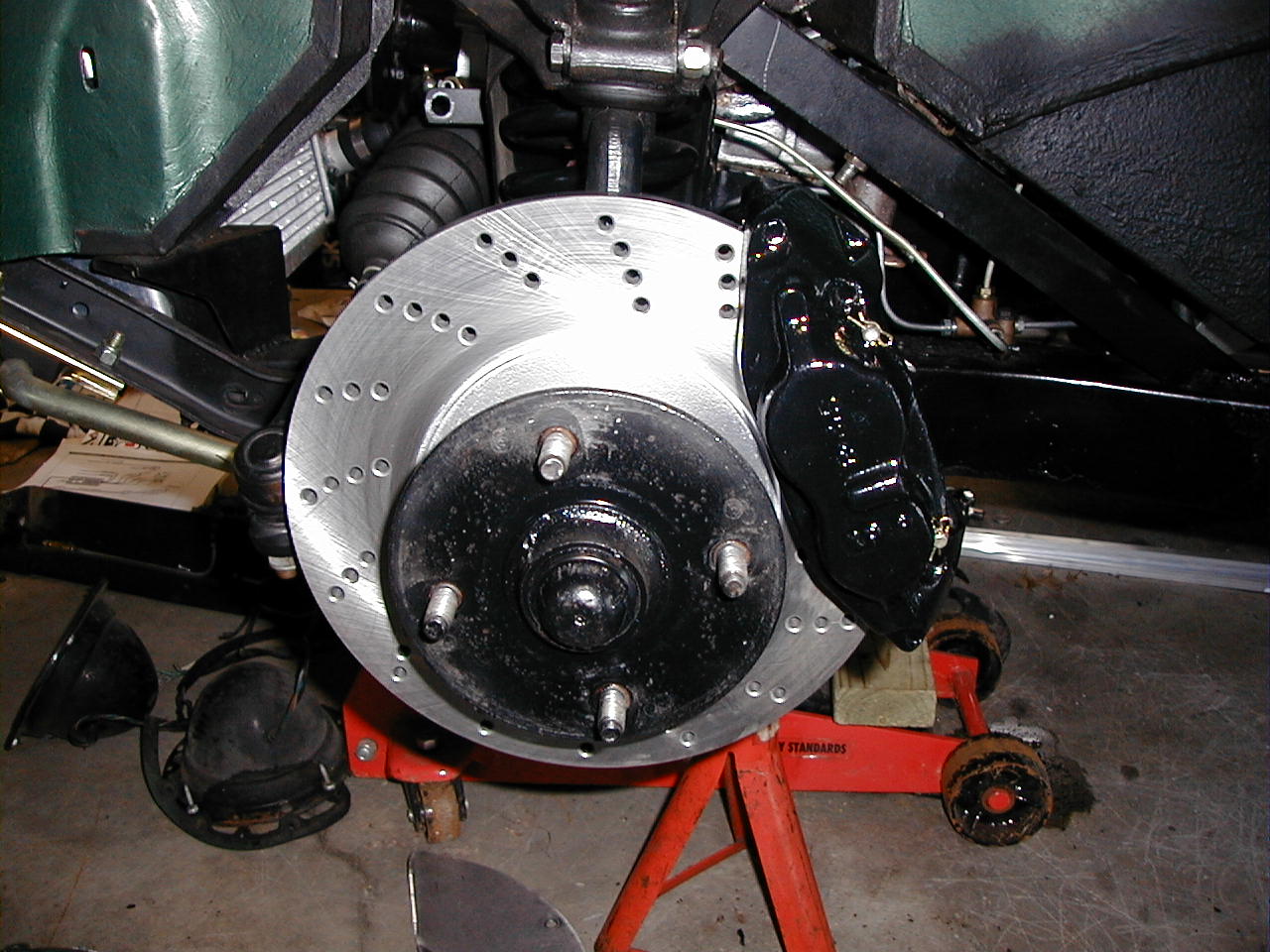

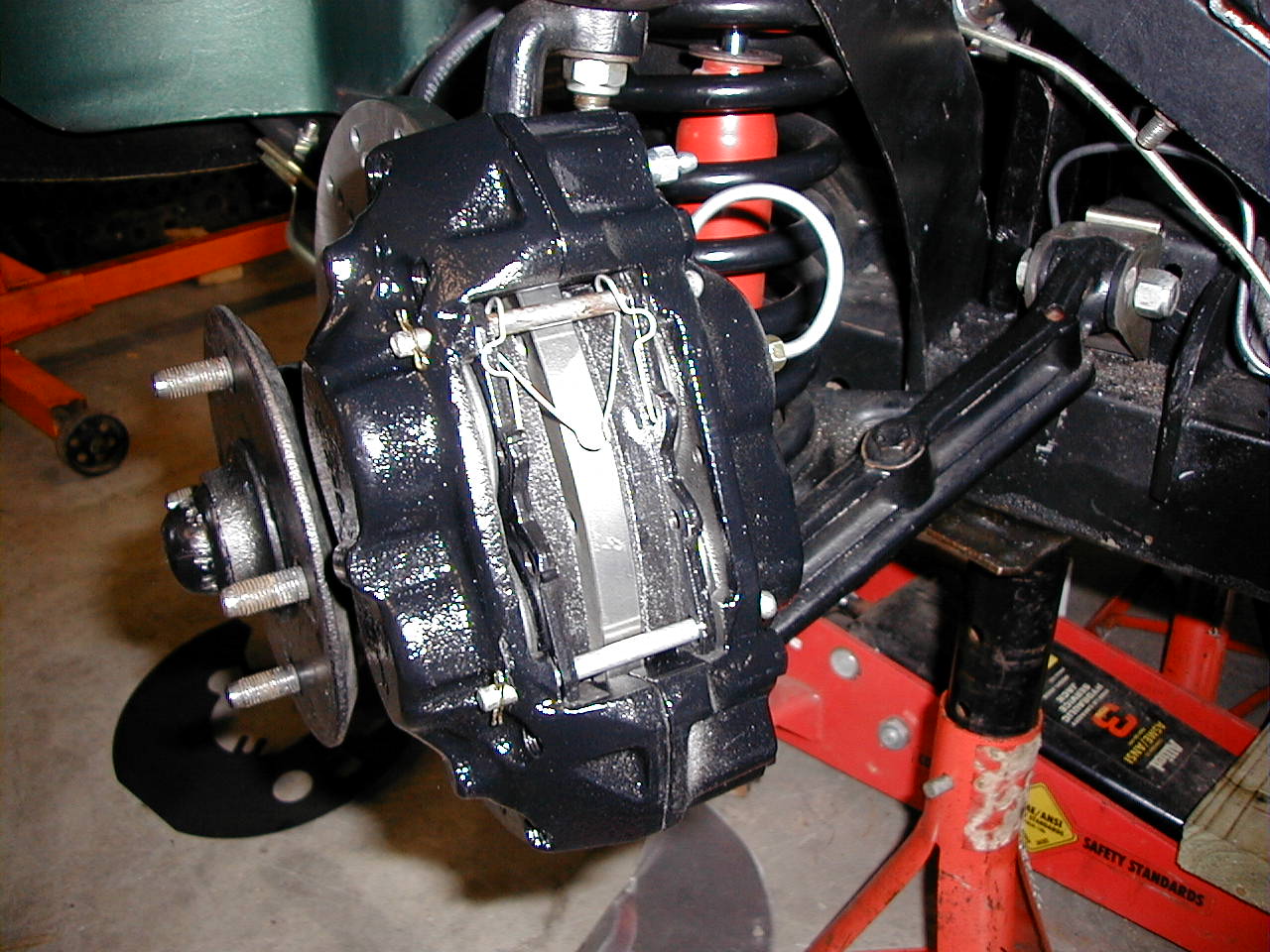

While I was looking at the car this

spring, I took at look at what was possible as far as brake

upgrades are concerned. The goal was to upgrade the braking

without making major changes. The VTR site has a tech article on

using Toyota 4 piston calipers as a straight swap. Turns out you

an get these at Autozone for as little as $35 each if you have

the old cores. I bought an old set on Ebay for $25 and

confirmed they fit. The high performance pads ended costing more

than the calipers. I also bought a set of cross drilled rotors (Brembos)

to complete the high performance brake upgrade. Below are old

and new photos, as well as a comparison of the calipers. This is

a simple upgrade that should be quite effective.

|